Bushings vs. roller bearings: why do ThorPlas-Blue bushings perform so well?

Bushings vs. roller bearings: why do ThorPlas-Blue bushings perform so well?

Thermoplastic bushings and roller bearings are both types of bearings used in mechanical applications, but they are each better suited for different types of applications.

Thermoplastic bushings have a low coefficient of friction, making them ideal for low-speed rotating applications. They are also self-lubricating and have a high resistance to wear, which allows them to last longer in these types of applications. Additionally, thermoplastic bushings are lightweight and have a good resistance to impact, shock and vibration which makes them suitable for applications that require a high degree of flexibility. They are also corrosion resistant, which makes them ideal for use in harsh environments. Roller bearings, on the other hand, are better for high-speed rotating applications as they can handle higher loads and have less drag.

When choosing between these two types of bearings, it’s important to consider the specific requirements of the application, such as the load, speed, and environment.

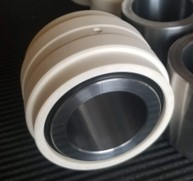

ThorPlas-Blue is Thordon’s Thermoplastic grade of material which was specifically formulated for use in low speed and oscillating applications, as well as high pressure industrial and marine applications. This material is homogeneous and self-lubricating, offering low friction, high strength and good abrasion resistance. These characteristics make ThorPlas-Blue ideal for low speed, high pressure applications in hard to reach industrial environments that require minimal downtime.

Putting Thordon Bushings to Work in Wastewater Treatment

The Expensive Problem: Roller Bearings on a Cake Distribution Screw Conveyor in a wastewater treatment plant were failing frequently because of seizing due to sand and grit getting into the bearings by way of mixing with the grease. The cost per roller bearing is $3k and each screw conveyor has 6 bearings, which makes it very costly to replace them frequently.

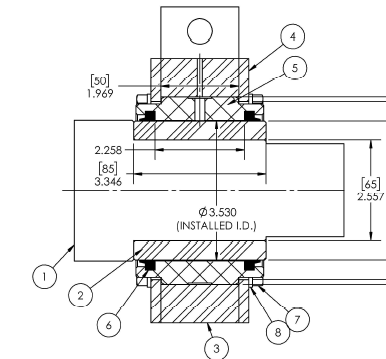

Thordon’s Efficient, Cost-Effective Solution: The Roller Bearing Housings were slightly modified to fit them with a self-lubricating Thordon bushing and two wiper seals. The seals help keep the sand and grit out of the bearing area to prolong the wear life of the bushing. The shaft was fitted with a stainless steel sleeve to provide a smooth finish for the bushing to slide on. The new assembly will never seize as the bushing is designed to run with a larger clearance than that of a roller bearing. This change saved thousands of dollars in operation and maintenance costs.

Do you have expensive challenges with your bearings and need a creative, cost-effective solution? Allow Millstream Engineering’s team of specialists to lead your group to a successful, economical solution. Contact us today.