Hydropower Tech Tips – What are “Block-style” Turbine Guide Bearings?

Hydropower Tech Tips – What are “Block-style” Turbine Guide Bearings?

BLOCK STYLE – THE OLDEST TURBINE GUIDE BEARING DESIGN!

This style of adjustable turbine guide bearing dates back to the early 1900’s when water-lubricated bearing material choices really only included wood or rubber. The block bearing is most commonly seen in older and smaller units, and can be in a vertical or horizontal orientation. The tropical hardwood known as lignum vitae was most commonly used at the time, as it demonstrated reasonable wear life and the resins in the wood provided some self-lubricating capability.

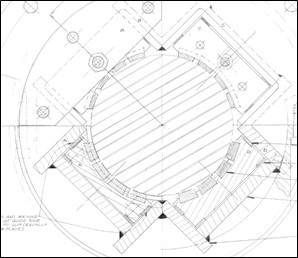

These style of bearings can be built with solid blocks fitted into 3 or 4 simple rectangular pockets around the shaft, or can include some mechanism to allow for periodic adjustment of clearance to compensate for wear by gradually moving the pads in toward the shaft using a wedge shaped backing plate and screw adjustment.

Adjustable Block Design

Housing Pocket & Shaft

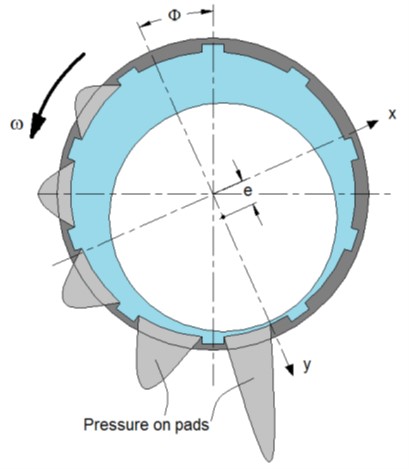

LIMITED LOAD CAPACITY & FREQUENT ADJUSTMENTS

The block style of guide bearing has limited load carrying capability compared with a cylindrical bearing due to the large gaps between the supporting pads of bearing material. These gaps allow the cooling water to by-pass the loaded areas of the bearing, and cannot create a hydrodynamic film as efficiently as the full-form cylindrical bearings used in modern water lubricated designs.

Depending on material selection and turbine condition, frequent replacements or adjustments can be required to compensate for the wearing of the block material. Customers have noted that it can take 1 week or more of downtime to make these adjustments (de-water, lock-out, remove packing, adjust bearing, re-assemble, un-lock, re-water). The oil bearing above the turbine bearing is also working with a tight clearance, so if the block bearing clearance is allowed to get too large, there is also some risk of overloading the oil/babbitt bearing above it.

Limited Load Support

Laminate Blocks

Rubber Blocks

Wood Blocks

OPTIMIZING BEARING LIFE THRU MATERIAL SELECTION

A good first step to extending service life of a block bearing is to use a self-lubricating elastomer bearing material, and an even better second step is to consider switching to a modern cylindrical bearing configuration. The next post will present some real-life examples where Thordon SXL was used to improve life of these block-style guide bearings with several of our customers in Canada, so make sure to follow Millstream on LinkedIn to find out!

Do you have challenges with your bearings, shaft seals, or water filtration systems and need a creative, cost-effective solution? Allow Millstream Engineering’s team of specialists to lead your group to a successful, economical solution. Contact us today.