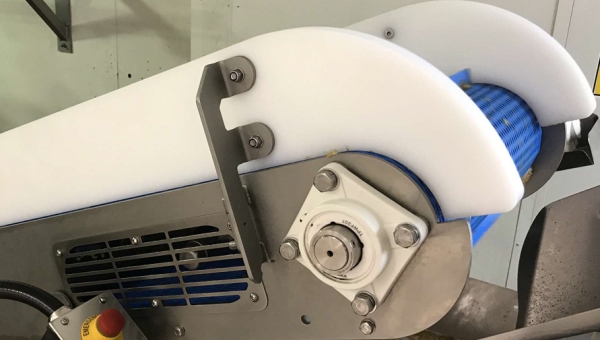

“Industry Ready” Direct Fit Bearings

Bolt-in Solutions to Extend Time Between Replacements.

Take Advantage of Our Experience With Proven Designs

We’ve figured out the details, so you just need to bolt in a superior bearing solution and extend your operating time.

Hanger Bearings

These proven Thordon screw conveyor hanger bearings are available in a variety of material grades, styles, and sizes depending on the application. The most common applications are in materials handling, mining, sewage/wastewater treatment, and other industrial process equipment.

Bearing Material Information

All of our “Industry Ready” bearing solutions use proprietary self-lubricating materials manufactured by Thordon Bearings. Material grade options and properties are summarized here.

|

Thordon XL |

Thordon SXL |

|

ThorPlas-Blue |

ThorPlas-White |

|

| Temperature Limit | 60°C (140°F) | 60°C (140°F) | 80°C (175°F) | 80°C (175°F) | |

| OK for Dry Start Up? |

NO | YES | YES | YES | |

| Resistance to Abrasives? | Moderate | Good | Good | Good | |

| Drinking Water Certified? | NO | NO | NO | YES | |

| General Remarks | Good balance between abrasion resistance & low friction. | Lowest friction, suitable for limited dry-start. | Preferred choice for higher loading, or higher operating temperatures. | Best material for food-grade applications requiring NSF/ANSI 51 certification. |

General Design Guidelines

Bearing Pressure

Sliding Speed

Wall Thickness

Mating Surface

Fitting Methods

Machining Tolerances

Customized Solutions

If you don’t see what you need here, or want to modify an existing solution – let us know! We can offer competitive customized solutions for most of the products shown.