Aneya Foundries

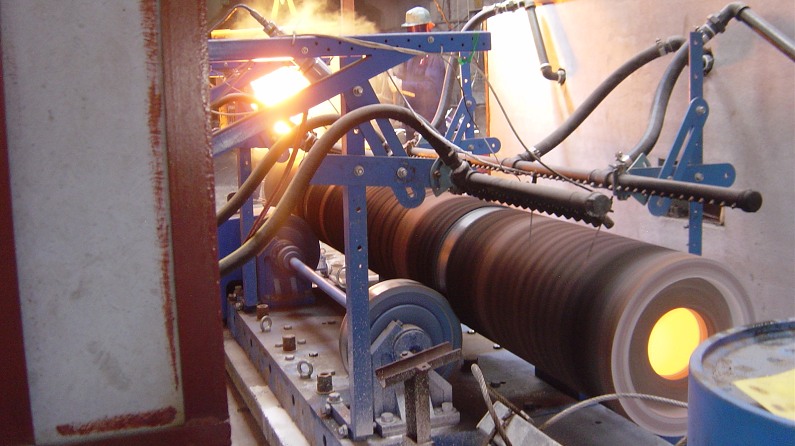

Expertise in Centrifugal Casting of Custom Copper Alloys to Meet Your Unique Requirements

Offering competitive pricing for fully finished bronze components, with a wide range alloys available!

Gearbox Bushing

300mm OD, with integrated grease passages

Crosshead Bushing

250mm (10") OD x 500mm (20") length

Wrist-Pin Bushing

75mm (3") OD, with grease groove

Square Sliding Block - Steering Gear

260mm (10.5") x 250mm (10") x 150mm (6")

Split Bronze Flange

Complete with Mounting Holes

Thrust Washer

With Lubrication Groove

Marine Propulsion - Shaft Sleeve

585mm (23") OD x 2m (72") length

Double Flanged Bushing

410mm (16") OD x 240mm (9.5") length

Heavy Flanged Bushing

With Integrated Seal Grooves

Flanged Bearing Housing

With Split Retaining Ring

Complex Hollow Shapes

Using Sand Casting Methods

Custom End Covers for Chiller

635mm (25") OD x 225mm (9") Length

Rotor Lock Bushing

355mm (14") OD x 355mm (14") Length

Bronze Stator Rings

280mm (11") OD, fitted with anti-rotation pins

Custom Flanged Bearing Housing

For Water Lubricated Bearing