Water Lubricated Bearings

Solving Your Bearing Wear Life Problems

Eliminate Oil-lubricated Bearings, Reduce Maintenance & Extend Bearing Wear Life with Water Lubrication

Water lubricated bearings have been used for hundreds of years, find out why they are still the bearing of choice today for oil-free pumps and hydro-turbines.

Pump Bearing Material Selection Guide

|

Thordon XL |

Thordon SXL |

Thordon Composite |

ThorPlas-Blue |

ThorPlas-White |

|

| Temperature Limit | 60°C (140°F) | 60°C (140°F) | 60°C (140°F) | 80°C (175°F) | 80°C (175°F) |

| OK for Dry Start Up? |

NO | YES | NO | YES | YES |

| Resistance to Abrasives? | Moderate | Good | Excellent | Good | Good |

| Drinking Water Certified? | NO | NO | NO | NO | YES |

| General Remarks | Good balance between abrasion resistance & low friction. | Lowest friction, suitable for limited dry-start. | For use in highly abrasive environments. | Preferred choice for chemical solutions and higher operating temperatures. | Best solution for drinking water applications requiring NSF61 certification. |

Turbine Guide Bearing Material Selection Guide

|

Thordon SXL |

Thordon Composite |

ThorPlas-Blue |

|

| Temperature Limit | 60°C (140°F) | 60°C (140°F) | 80°C (175°F) |

| Filtered Water Supply? | YES – Recommended | Not Required | YES – Recommended |

| Resistance to Abrasives? | Good | Excellent | Good |

| Size Limitation? | NO | NO | Limited to ~400mm shaft OD for full cylindrical form |

| General Remarks | Best all-around combination of abrasive resistance, low starting friction, long wear life. | Best for use in highly abrasive environments. | Preferred choice for tighter clearances, or for lower cooling water flow rate. |

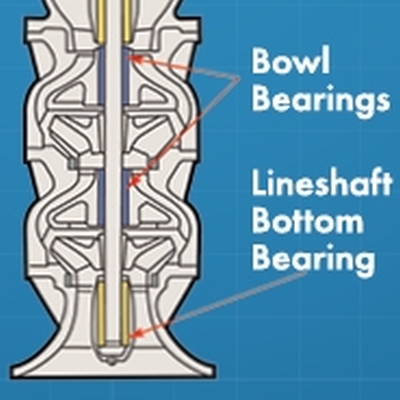

Typical Vertical Pump Bearing Applications

Hydro Turbine Guide Bearing Applications

General Design Guidelines

Bearing Pressure

Bearing pressure is calculated by considering the bearing load over the contact area, and each material grade will have a maximum design limit.

Sliding Speed

The sliding velocity or peripheral shaft speed is an important factor used to evaluate the frictional heat generation in a bearing which will determine the minimum cooling water flow rates required.

Wall Thickness

Minimum wall thickness is determined by the interference fit required to secure it within the housing, but should not be less than the minimum recommended amount for any given size. The wall thickness of the bearing also influences bearing clearance, since thermal expansion and water absorption allowances are proportional to the wall thickness. A thicker bearing wall will expand and contract more with water absorption or thermal expansion effects, so when possible, it is recommended to minimize the wall thickness to achieve a tighter clearance.

Mating Surface

The mating surface should be made of a corrosion resistant metallic material, with a hardness in the range of 20 Rockwell C when possible. The surface finish of the mating surface should be reasonably smooth according to good machining practice; for optimum performance with Thordon materials, a surface finish of 0.8 micro-meters (32 micro-inches) is recommended.

Fitting Methods

Polymer bearings are usually fitted with an interference fit or bonded using an epoxy adhesive. If interference fitting is used, it is easiest to freeze fit the bearings. In cases where freeze fitting is not possible, bearings can also be press-fitted.

Machining Tolerances

Polymer bearings do not necessarily need to be machined to the same tight tolerances as metal bearings to achieve optimum performance. Consult Millstream for correct bearing sizing and machining tolerances for your application.

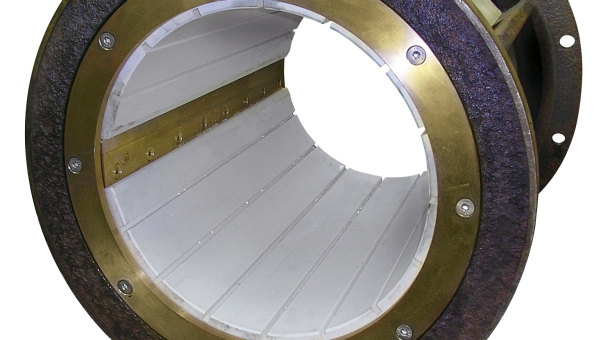

Lubrication Grooves

Lubrication grooves are machined or molded in the bearing to help the flow of water through the bearing. The grooves also provide a pathway for the abrasives to exit the bearing.