Before exploring the advantages of centrifugal cast bronze components, it’s essential to gain a foundational understanding of what centrifugal casting is and the distinct characteristics of bronze as a material.

Bronze: An alloy primarily of copper and tin, bronze is known for its strength, ductility, and corrosion resistance. The addition of other elements like phosphorus, aluminum, and silicon can enhance specific mechanical and material properties.

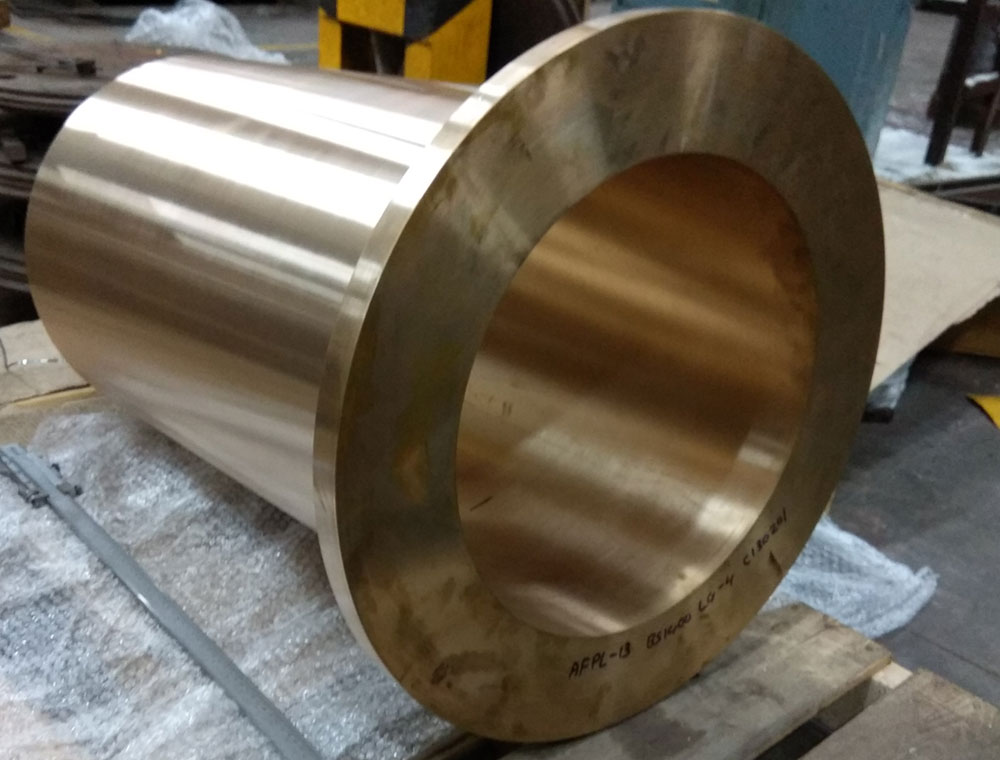

Centrifugal Casting: This process involves pouring molten metal into a rotating mold. The centrifugal force drives the metal towards the mold walls, creating a dense and homogenous structure. This technique is particularly effective for manufacturing symmetrical parts like sleeves, bearing housings, wear rings, and flanged components.

To understand the full potential and benefits of using bronze in industrial applications, let’s delve into the specific advantages of centrifugal cast bronze components, a choice that stands out for exceptional quality and performance.

Uniform Density: Centrifugal casting ensures consistent material density, eliminating internal voids and impurities. This results in components with superior mechanical properties.

Customizability: The process allows for the creation of complex shapes and sizes, offering flexibility in design and application.

Corrosion Resistance: Bronze inherently resists corrosion, making it ideal for components exposed to harsh environments, such as marine or chemical applications.

Wear Resistance: The hard surface of bronze withstands wear and tear, extending the lifespan of components in sliding or rotating applications.