Freeze-Fit vs. Press-Fit for ThorPlas-Blue? Pros & Cons

Freeze-Fit vs. Press-Fit for ThorPlas-Blue? Pros & Cons

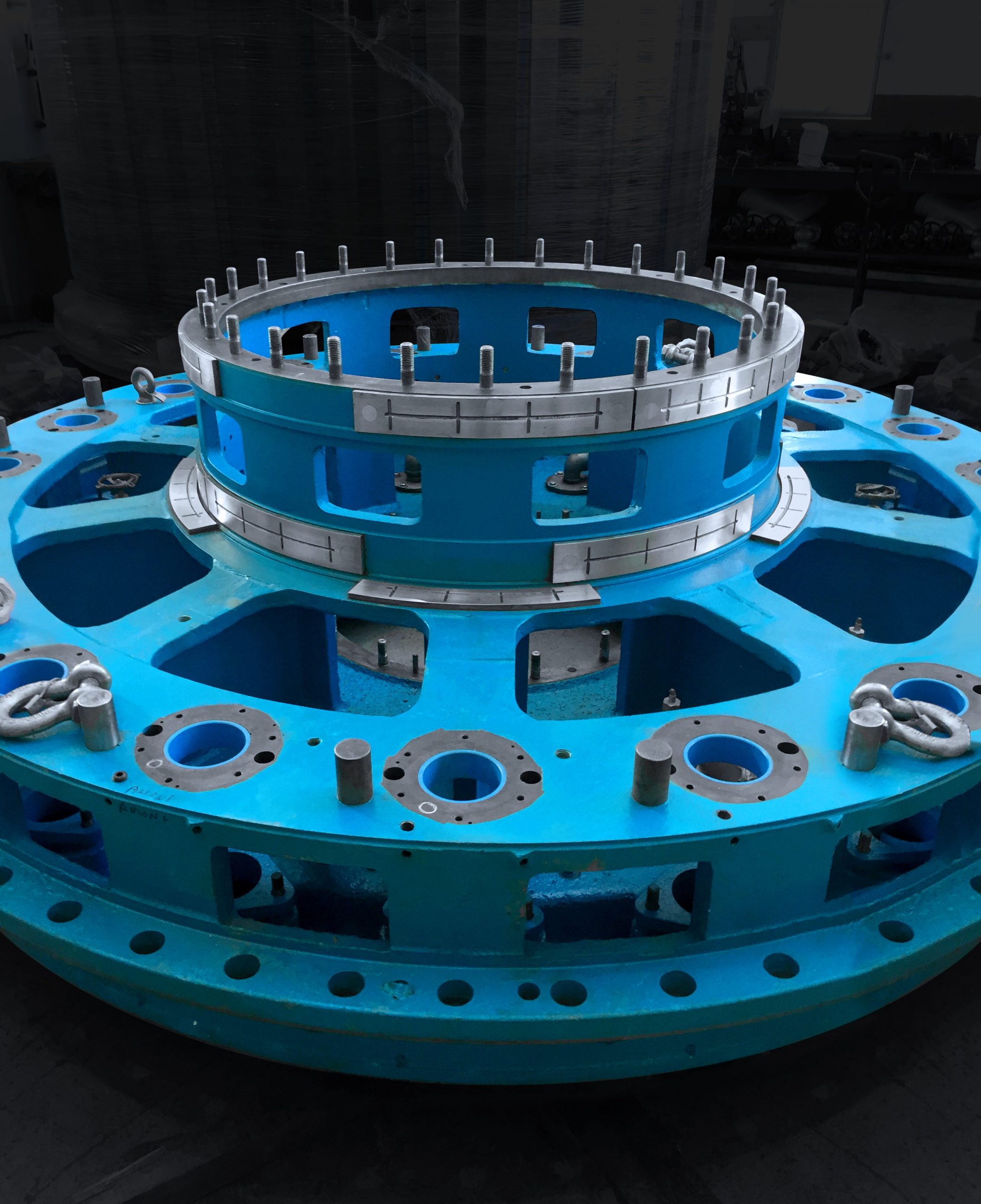

Understanding ThorPlas-Blue

Freeze-Fitting ThorPlas-Blue Bushings with Dry Ice or Liquid Nitrogen Vapor

Minimal Stress

Freeze-fitting places minimal stress on the polymer bushings, preserving their mechanical properties and dimensional stability.

Precision

Both dry ice and liquid nitrogen methods allow precise control over interference fits, ensuring secure and accurate installation.

Ease of Assembly

The process is relatively straightforward and accessible, requiring minimal specialized equipment or training.

Uniform Cooling

Freeze-fitting ensures uniform cooling, achieving consistent interference fits, even for complex components.

Safety Concerns

Handling dry ice and liquid nitrogen poses safety risks, including skin burns and cold-related injuries.

Availability

Access to dry ice or liquid nitrogen may be limited in some areas, affecting feasibility.

Equipment & Expertise

Specialized equipment and training may be necessary, and the process can be time-consuming.

Press-Fitting ThorPlas-Blue Bushings

Versatility

Suitable for various applications, including those where temperature control is challenging.

Speed

Generally faster, making it suitable for high-volume production.

Precision

With careful control, precise interference fits can be achieved, ensuring a secure connection.

Cost-Effective

Often cost-effective, as it doesn't require specialized consumables or equipment.

Ease of Assembly

The process is straightforward and accessible, requiring minimal training or expertise.

Stress Generation

Press-fitting can generate localized stresses in the bushing, potentially affecting performance.

Equipment Requirements

Specialized equipment may be needed, which can be costly and impractical for some operations.

Risk of Damage

Improper execution can damage the bushing or mating components, increasing costs and time.