Freeze Fitting: The easy & efficient way to install thordon bearings

Freeze Fitting: The easy & efficient way to install thordon bearings

When it comes to installing Thordon bearings with an interference fit, freeze fitting emerges as the simplest and most cost-effective method. Thordon’s unique material properties, characterized by a high coefficient of thermal contraction/expansion, make it contract significantly when cooled. In this article, we will explore the process of freeze-fitting Thordon bearings, the use of cooling agents, and the required precautions during installation.

Freeze-fitting Thordon bearings eliminate the need for expensive jacking or specialized equipment, making the installation process hassle-free. Thordon’s high coefficient of thermal contraction/expansion allows for easy fitting when cooled, ensuring a secure interference fit without the use of excessive force.

Liquid nitrogen is the optimal cooling agent for freeze-fitting Thordon bearings. However, if liquid nitrogen is not available, dry ice can be used for most installations. It is important to note that when freeze-fitting Thordon Composite or ThorPlas Bearings, dry ice should be used instead of liquid nitrogen.

When using liquid nitrogen, it should be contained tightly to prevent leakage. The bearing should be fully immersed in or evenly coated with liquid nitrogen. Once the vapor stops boiling off, indicating a temperature of -196°C (-320°F), the bearing is ready for easy installation. The time required for cooling and contraction typically ranges from 5 to 30 minutes, depending on the bearing’s surface area.

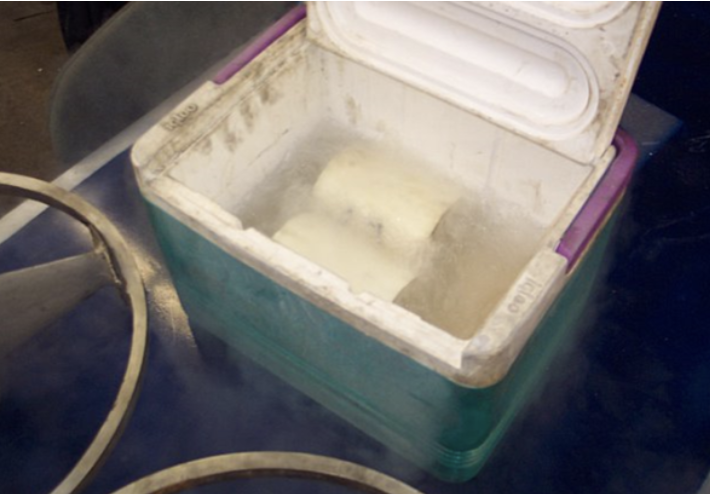

If dry ice is the chosen cooling medium, it should be supplied in pellet or small broken pieces, rather than block form. The dry ice should be tightly packed around the outer diameter (O.D.) of the bearing, ensuring contact with both the inside and outside surfaces. After three hours packed in dry ice, the bearing dimensions can be checked to determine if sufficient shrinkage has occurred for easy installation. If needed, the bearing can be re-packed for an additional hour.

It is important to exercise caution when using liquid nitrogen or significant quantities of dry ice in closed or poorly ventilated areas. The gases released during the process can displace oxygen and pose a risk to human health. Proper ventilation and adherence to safety guidelines are crucial during freeze-fitting procedures.

Freeze-fitting Thordon bearings offer a straightforward and efficient installation method, leveraging the material’s unique thermal properties. Whether using liquid nitrogen or dry ice, this process ensures an interference fit without the need for expensive equipment. However, safety precautions must be followed to prevent any risks associated with cooling agents.