A Comprehensive Guide to Machining ThorPlas-Blue: Tips and Techniques

A Comprehensive Guide to Machining ThorPlas-Blue: Tips and Techniques

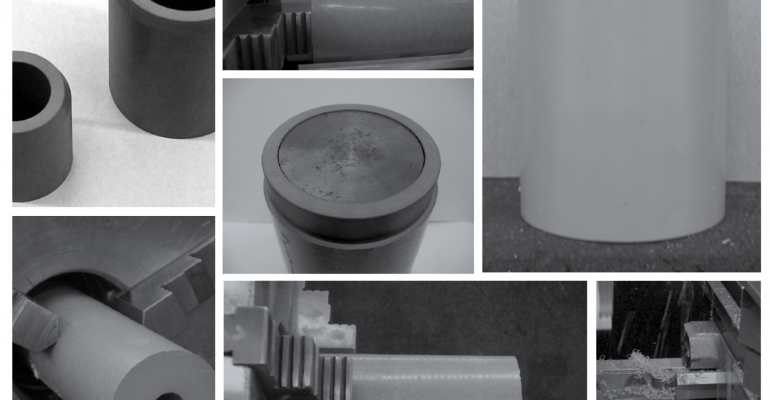

Machining ThorPlas-Blue, a high-performance material known for its durability and reliability, requires precision and care to achieve fine tolerances and high-quality results. Whether you’re working on ThorPlas-Blue bearings for industrial, pump or hydro applications, this guide will provide you with a step-by-step approach and essential tips for machining this exceptional material.

Understanding ThorPlas-Blue

ThorPlas-Blue is a versatile material that can be milled, sawed, planed, drilled, tapped, and threaded. Its characteristics make it ideal for various engineering applications. However, to harness its full potential, you need to follow specific guidelines to ensure a smooth machining process.

Material Preparation

Before you dive into machining ThorPlas-Blue, you should consider the following steps:

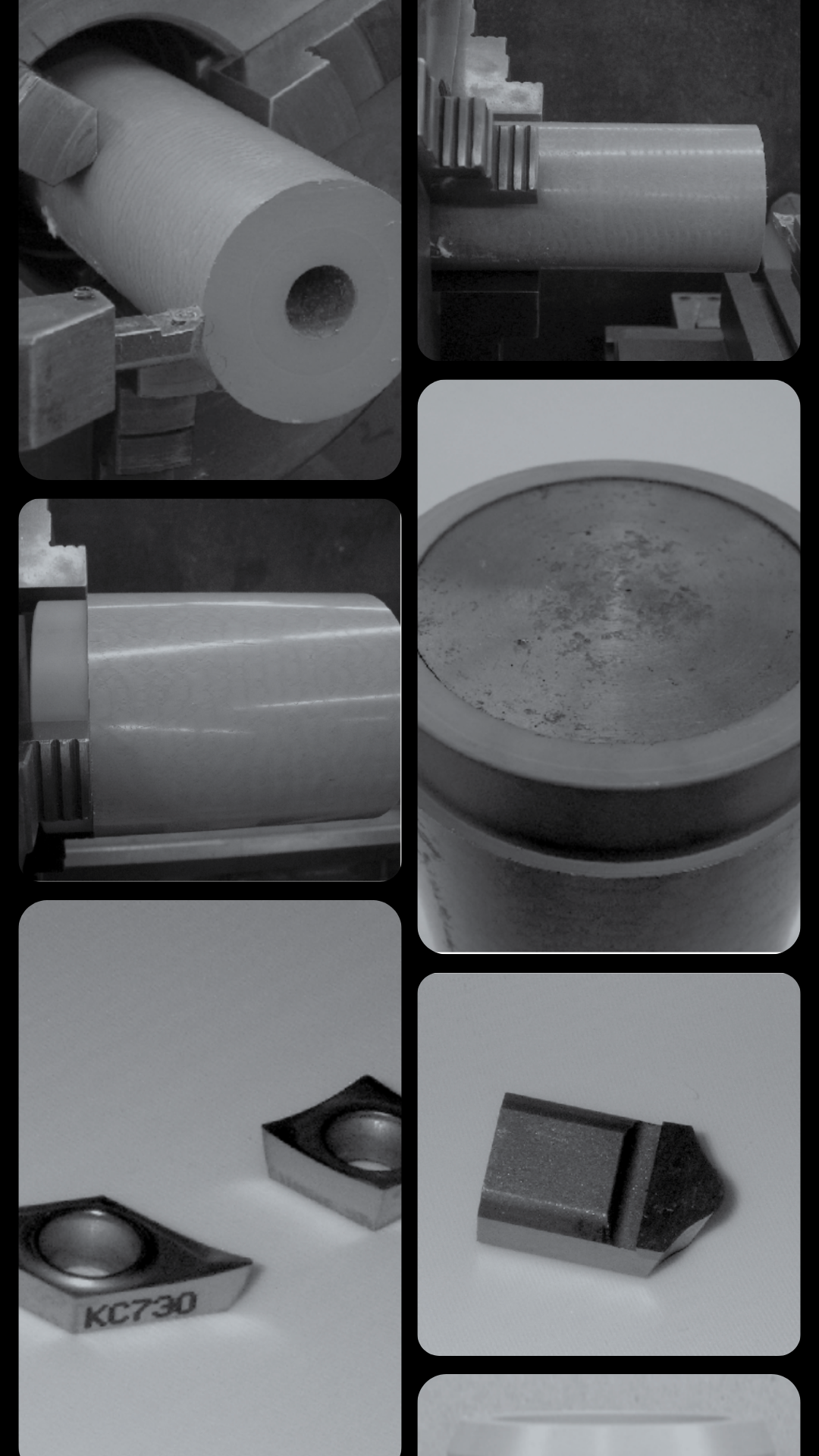

- General Machining: When selecting your tools, opt for sharp tools with carbide-grade tips and fast speeds to enhance precision. Ensure that you have adequate material length (between 25 to 40 mm) for chucking and holding your part securely.

- Support and Clamping: While clamping your workpiece, make sure not to over-clamp, as this can lead to material cracking. Providing good support to the part is crucial to prevent damage and ensure a successful machining process.

- Cutting Speeds: For ThorPlas-Blue materials, typical cutting speeds range between 150 to 300 m/min (492 to 985 fpm), depending on the diameter of your workpiece.

Groove Cutting

For applications where water grooves are necessary, broaching using custom-made cutting tools is recommended. These tools are used to produce specific dimensions for water grooves as required for your project.

Chamfers

Chamfers are crucial for easing the installation process and enhancing the overall functionality of ThorPlas-Blue bearings. The dimensions for machining chamfers vary according to the bearing length:

Metric

- Below 25 mm: 1.5 mm x 25°

- 25 mm to 100 mm: 3.0 mm x 25°

- Over 100 mm: 5.0 mm x 25°

Imperial

- Below 1 inch: 1/16” x 25°

- 1 inch to 4 inches: 1/8” x 25°

- Over 4 inches: 1/4” x 25°

Step-By-Step Machining Process

To machine ThorPlas-Blue effectively, follow these eight steps:

- Cutting and Chucking: Begin by cutting the part with extra length for chucking, parting off, and facing. For larger parts, use an internal plug or chucking ring for added support.

- Setting in Chuck: Set the part in the chuck jaws with moderate clamping force. Avoid over-clamping to prevent material stresses and cracking.

- Machining the Chucking Ring: For parts requiring a metal chucking ring, machine the I.D. of the chucking ring to have a slight interference with the ThorPlas material. Machine the OD of the ring slightly to clean any uneven surfaces.

- Tool Selection: Ensure you have sharp and smooth tool bits for machining the ThorPlas material. Different bits are used for machining the I.D. and O.D.

- Machining the O.D.: Machine the bearing’s outer diameter using the appropriate tool bit.

- Wall Thickness Machining: Use a tool bit and a boring bar to machine the bearing’s wall thickness. Clear the I.D. of chips or shavings to maintain tolerances and reduce heat buildup.

- Broaching Grooves: If required, broach grooves in the bearing, ensuring there’s sufficient chucking allowance to accommodate cuttings or streamers.

- Parting Off and Chamfering: Part the bearing to length using a parting tool, supporting it during the cut. Afterward, machine chamfers to ease installation.

Machining Tolerances

For detailed information about machining tolerances, you can refer to Section 4(g) on page 16 of the ThorPlas Engineering Manual.

Conclusion

Machining ThorPlas-Blue demands precision and attention to detail, but it’s a rewarding process, as it enables you to create durable, reliable components for various applications. By following the guidelines provided in this comprehensive guide, you can achieve fine tolerances and high-quality results in your machining projects involving ThorPlas-Blue. Whether you’re an experienced machinist or just starting out, this guide should serve as a valuable resource for your machining endeavors.