Case Study: Revolutionizing Wastewater Treatment: Millstream’s Innovative Solution for Grease-Free Efficiency

Case Study: Revolutionizing Wastewater Treatment: Millstream’s Innovative Solution for Grease-Free Efficiency

Wastewater treatment plants play a crucial role in maintaining environmental sustainability, but they often face challenges that can disrupt operations and increase maintenance costs. In this case study, we explore a significant issue encountered by a wastewater treatment facility and explore how Millstream’s innovative solutions are set to revolutionize wastewater treatment applications.

The Challenge

At a wastewater treatment plant in Ontario, the lifting screw mechanism on large wastewater inflow gates was facing premature wear, attributed to the difficulty in maintaining adequate grease lubrication along the full length of the actuating screw. The facility had to regularly grease the screws to ensure their proper operation, leading to frequent downtime and escalating maintenance costs. The weight of the gate, coupled with the hydraulic forces from the flow of wastewater when closing, posed additional challenges.

The Original Design

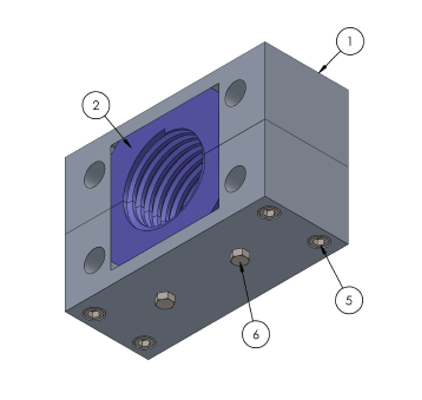

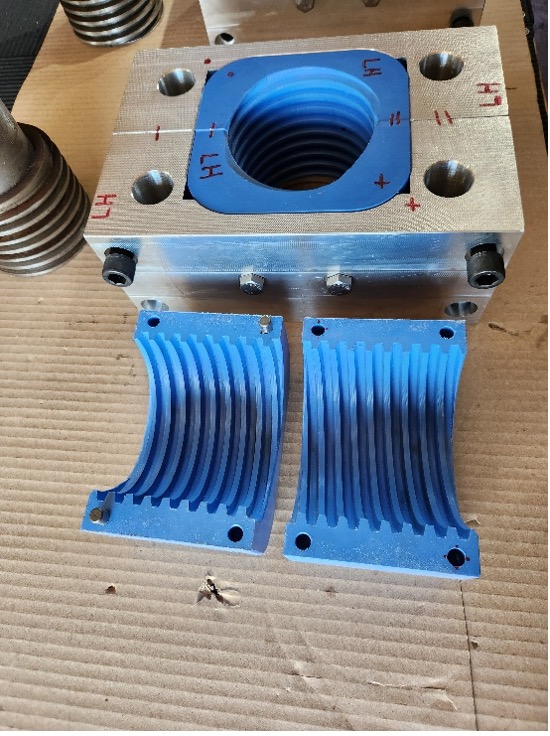

The original split screw nuts were crafted from bronze, with a spare set also having been machined from aluminum (shown below). The original bronze nuts were quite expensive, and without constant greasing, there was risk of binding and damage to the square threads. The need for constant greasing not only increased maintenance efforts but also proved to be a temporary fix to a persistent problem.

The Millstream Approach

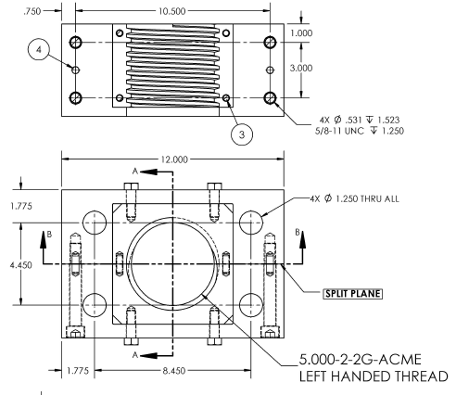

When approached by the wastewater treatment facility for a solution, Millstream engineers decided to redesign the split screw nuts. The key innovation is the incorporation of Thordon’s unique ThorPlas-Blue self-lubricating bearing material as a replaceable threaded insert, fitted inside of a split aluminum housing that matches the mounting conditions of the original design. This innovative design eliminates the need for regular greasing, as well as providing a solution that will reduce the frequency of maintenance required on the screw mechanism. In case of future service and repair, only the inner threaded ThorPlas-Blue insert will require replacing, substantially reducing the repair cost compared with the original split bronze nuts used previously

Benefits of ThorPlas-Blue

The ThorPlas-Blue self-lubricating material offers several advantages over the original aluminum design. Not only does it provide a durable and long-lasting solution, but the self-lubricating properties of the material also mean that constant greasing is no longer required. This not only reduces downtime but also minimizes maintenance costs, enhancing the overall efficiency of the operations.

Engineering Calculations for Reliability

To ensure the suitability of ThorPlas-Blue for this application, Millstream conducted a complete design review and supporting engineering calculations. The team calculated the maximum allowable axial load applied to the 4.5″ long ThorPlas-Blue insert threaded with a double-start ACME-type internal thread. The results were impressive, indicating that the thread strength in the ThorPlas-Blue material would provide a lifting capacity roughly 5x higher than the expected weight of the gate to be lifted, providing a significant safety margin for unexpected operating conditions.

Looking Ahead

With the redesigned split screw nuts incorporating ThorPlas-Blue scheduled for assembly in early 2024, the wastewater treatment facility is poised to benefit from reduced maintenance, increased operational efficiency, and prolonged equipment lifespan.

Conclusion

Millstream’s innovative approach to wastewater treatment challenges showcases the potential for transformative solutions in the industry. By leveraging unique materials like ThorPlas-Blue and engineering expertise, Millstream not only addresses immediate issues but also sets the stage for enhanced reliability and sustainability in wastewater treatment applications.