Case Study: Transforming Wastewater Treatment Reliability with Thordon Solutions

Case Study: Transforming Wastewater Treatment Reliability with Thordon Solutions

Date of Original Installation: Mid-2023

Industry: Sewage & Wastewater

End User: Wastewater Treatment Facility, Ontario, Canada

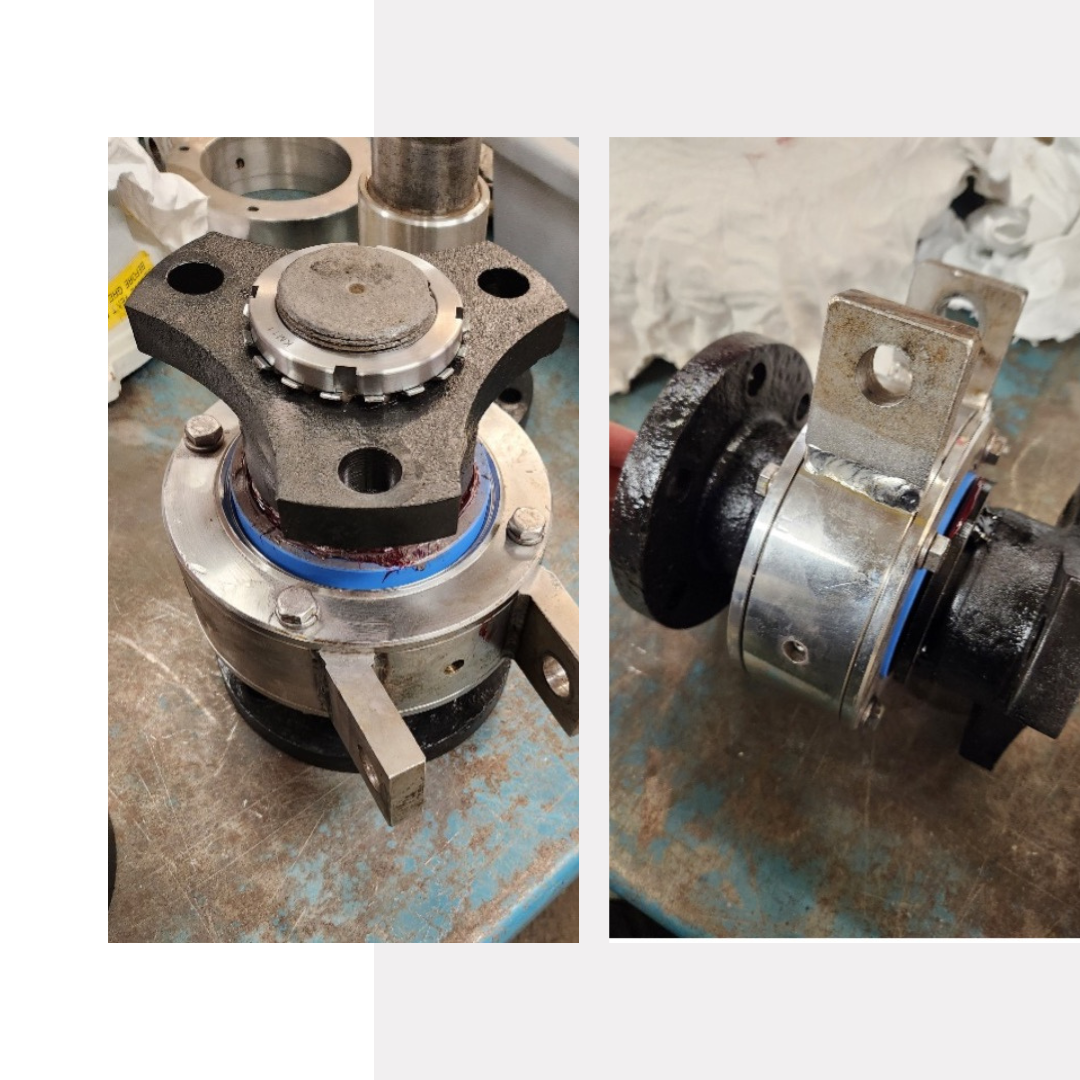

Application: Biosolids Screw Conveyor – Roller Bearing Upgraded to ThorPlas-Blue,

Thordon Grade: ThorPlas-Blue

About

Challenge

Solution

Result