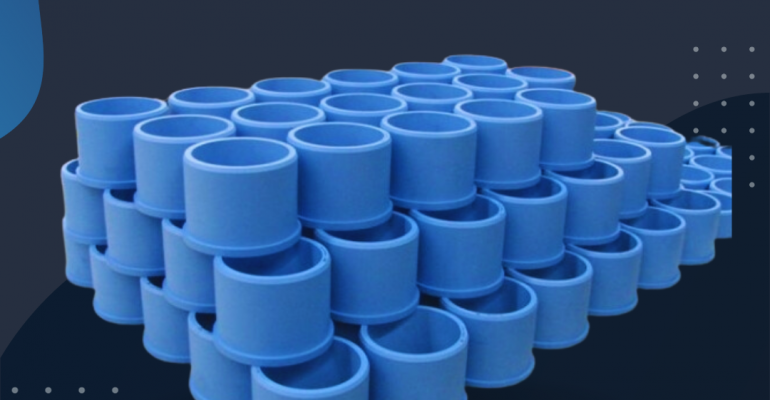

Navigating the world of self-lubricated and greaseless bushings can be complex, given the myriad of options and specific needs of different applications. At Millstream Engineering, we understand these intricacies. With our in-depth knowledge and expertise, we are poised to help you select the right self-lubricated bushing that aligns perfectly with your requirements. Through careful analysis and evaluation of your specific needs, we ensure you leverage the full benefits of these innovative products, maximizing efficiency and reducing long-term costs. Trust Millstream Engineering to guide you in making informed decisions that yield lasting benefits for your machinery and operations.Top of Form