Heavy Duty Hero: The Role of Bronze Components in Pumps and Industrial Equipment

Heavy Duty Hero: The Role of Bronze Components in Pumps and Industrial Equipment

Welcome back to the second part of our exploration into the versatile world of bronze castings. In “Part 1,” we delved into the critical roles that bronze plays in the hydropower and marine industries, highlighting its durability and corrosion resistance. Continuing our journey, we now turn our attention to the indispensable applications of bronze in the pump and heavy industrial sectors. As we uncover these applications, remember that Millstream Engineering is at the forefront of providing innovative bronze casting solutions. We encourage you to reach out for a no-obligation review and quote tailored to your equipment needs.

Pump Industry Applications

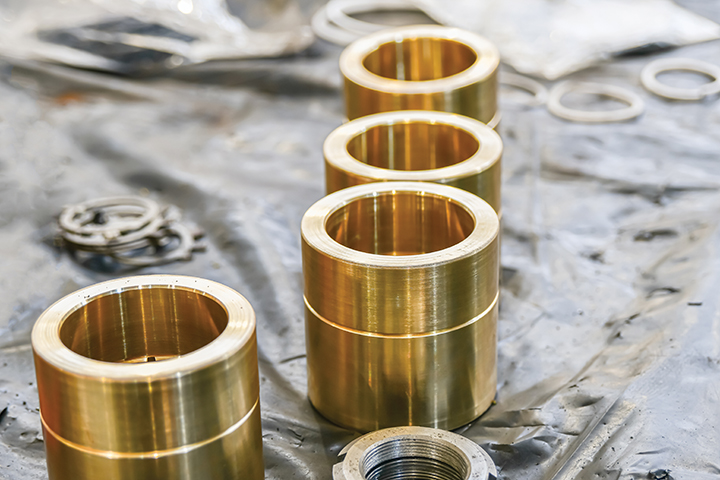

Bronze’s wear resistance and strength find extensive use in various types of pumps, including water, oil, and chemical pumps. Components like impellers and casings made from bronze offer reliability, especially in corrosive environments.

In the pumps industry, bronze is not just a material choice; it’s a performance enhancer. Beyond the commonly known impellers and casings, bronze is crucial in wear rings, gland packing, and shaft sleeves. These components benefit from bronze’s low friction and resistance to cavitation, especially in high-speed pumps used in fire protection and irrigation systems. For example, in municipal water treatment facilities, bronze cast components ensure efficient and reliable operation of high-pressure pumps, playing a pivotal role in maintaining consistent water supply.

Heavy Industrial Applications

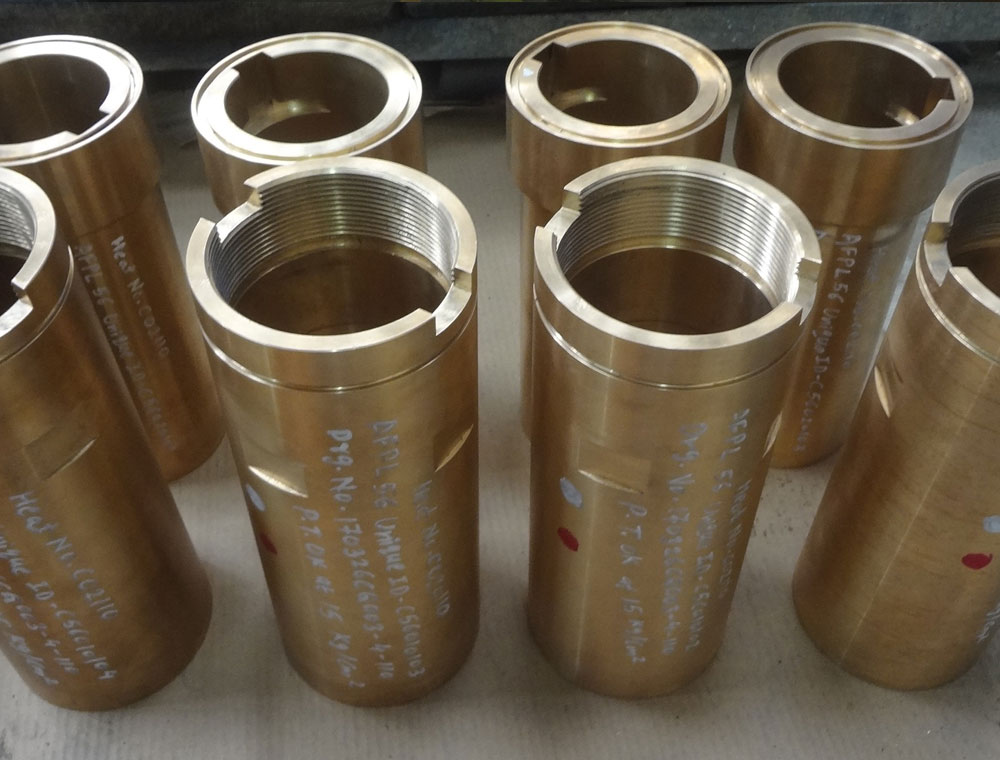

In the heavy industrial sector, bronze is a material of choice for its exceptional performance under demanding conditions. Machinery and equipment in these industries often rely on bronze for components like high-load liners and wear plates. This is particularly critical in sectors such as mining, where equipment operates under extreme conditions and demands materials that can withstand rigorous use.

Moreover, the breadth of bronze’s applications in heavy industry is vast. It is used extensively in load-carrying components for large industrial machinery such as presses, forging machines, and cranes. These types of machinery benefit from bronze’s ability to handle substantial loads and resist shock and wear, attributes that are vital for the efficiency and longevity of the equipment. In the steel manufacturing industry, bronze plays a critical role in liner plates found in rolling mill stands. Here, bronze components are subject to high temperatures and repetitive stress, yet their durability ensures continuous and efficient operation, which is essential for maintaining productivity in such a demanding industrial setting.

Bronze is also a key material in the construction of heavy-duty hydraulic and pneumatic systems, where its resistance to corrosion and metal fatigue makes it ideal for pistons and cylinder liners. These components are crucial in maintaining the functionality and safety of the systems, especially where they are exposed to harsh operational conditions.

Lastly, the customization potential of bronze is significant in the heavy industrial context. Due to its machinability and adaptability to various casting techniques, bronze parts can be tailored to specific requirements, addressing unique challenges faced by heavy industries. This adaptability allows for the design of bespoke components that meet the exact needs of complex and heavy-duty machinery.

The application of bronze castings in pumps and heavy industries further exemplifies the material’s unmatched versatility and resilience. From ensuring the smooth operation of high-pressure pumps to bearing the brunt in heavy machinery, bronze proves to be an indispensable ally in diverse industrial applications.

Millstream Engineering is committed to harnessing the full potential of bronze castings to meet your industrial needs. We invite you to leverage our expertise for your specific requirements. Contact us for a comprehensive application review and a no-obligation quote, and let us help you optimize the performance and durability of your equipment with our advanced bronze casting solutions.