The Underwater Workhorse: Bronze Keeps Machinery Moving in Hydropower and Marine

The Underwater Workhorse: Bronze Keeps Machinery Moving in Hydropower and Marine

In the realms of hydropower and marine engineering, the success and efficiency of machinery largely depends on the long-term reliability of the mechanical components. This is where bronze, a time-tested alloy, emerges as an underwater workhorse. Renowned for its strength, resilience to corrosion, and unparalleled durability, bronze is a key player in keeping the colossal machinery of these industries moving smoothly beneath the water’s surface. From the intricate components of hydropower turbines to the robust fittings of marine vessels, bronze castings ensure that these massive machines operate seamlessly, even in the most challenging underwater environments. Centrifugal casting, a method that enhances the mechanical properties of bronze by pouring molten bronze into a rapidly rotating mold, further elevates its suitability for these critical applications, making it an unsung hero in the aquatic depths of industrial machinery.

Hydropower Industry Applications

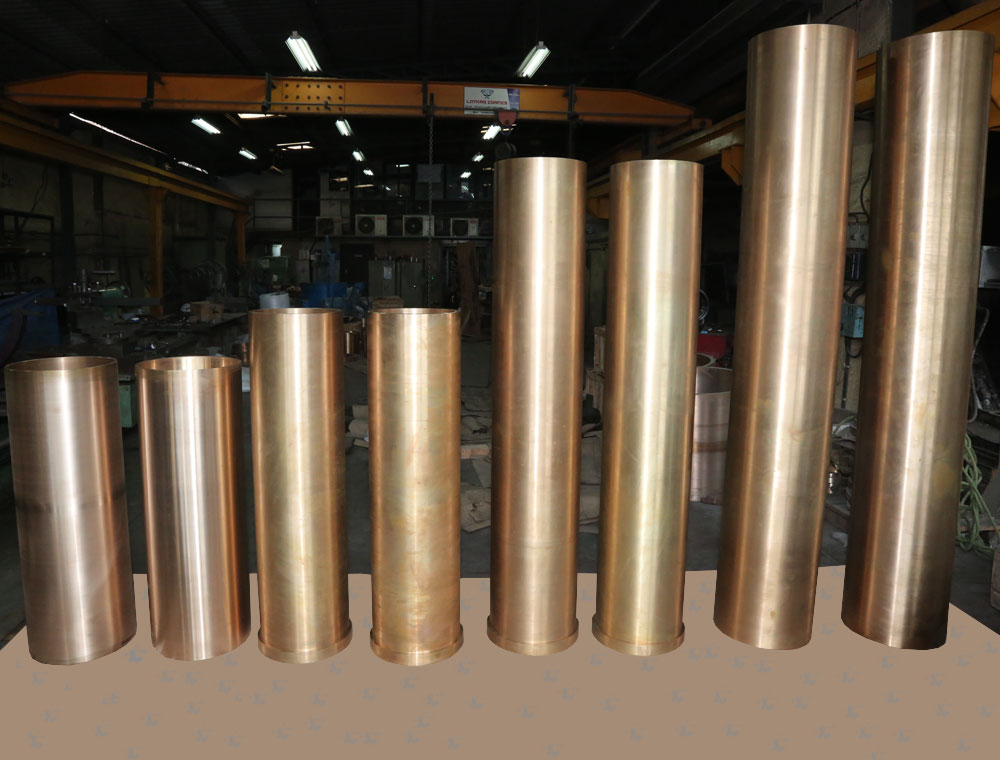

In the hydropower sector, the application of bronze castings is both diverse and essential, reflecting the industry’s need for durable and reliable materials. Bronze’s role extends beyond the construction of turbines and generators; it is pivotal in producing a range of components that withstand extreme conditions.

Furthermore, bronze finds its application in the mechanical components associated with main inlet valves, head gates and spillway gates, as well as the linkages and servo connections in the turbine regulating mechanisms. The bronze used in these settings is often of a specific alloy, tailored to withstand the unique combination of mechanical stress, corrosion, and wear present in the hydropower environment.

Marine Industry Applications

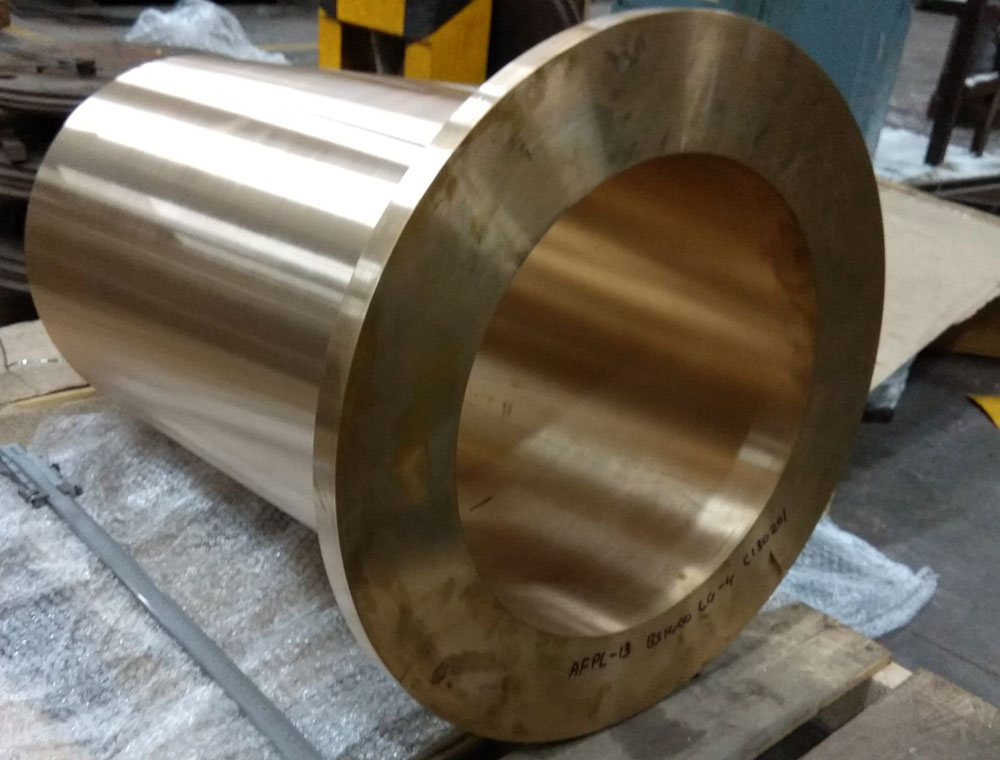

The marine industry, with its demanding saltwater environments, finds an invaluable ally in bronze due to its exceptional corrosion resistance. This industry harnesses the properties of bronze in a multitude of applications, essential for both the performance and longevity of maritime equipment. Key uses include propeller shaft sleeves, rudder stock sleeves, along with numerous components found in deck machinery and other vital onboard systems. These components, critical in ensuring smooth operation, stand up to the harsh marine environment, offering resilience against the relentless assault of saltwater corrosion.

Beyond these applications, bronze is also extensively used in the construction of hull fittings, valve components, and pump parts used throughout ships and submarines. Its ability to withstand not only saltwater but also varied temperature fluctuations and mechanical stresses makes it an ideal material for such applications.

In addition to these, bronze plays a pivotal role in the manufacturing of anchor winches, hoist mechanisms, and steering gears. The high strength and low friction coefficient of bronze ensure that these components operate efficiently, reducing wear and tear and thus prolonging their operational lifespan. This is particularly important in heavy-duty applications, such as in large cargo ships and naval vessels, where equipment reliability is paramount.

The versatility and reliability of bronze castings in these industries cannot be overstated. From the massive turbines of hydropower plants to the essential components of marine vessels, bronze stands out as a material that combines durability with exceptional performance. In our next post, we’ll delve into the critical role bronze plays in the pump and heavy industrial sectors, where its attributes are equally valued.

Moreover, at Millstream Engineering, we understand the unique demands of these industries and specialize in providing top-tier bronze casting solutions. We invite you to contact us for a no-obligation application review and quote. Whether you’re upgrading existing equipment or embarking on new projects, our team is equipped to offer expert advice and tailored solutions that align with your specific needs. Reach out to Millstream Engineering today to explore how our bronze casting expertise can enhance the performance and longevity of your equipment.