Case Study: Innovative Retrofitting at a Wastewater Treatment Facility

Case Study: Innovative Retrofitting at a Wastewater Treatment Facility

Client Background

The Challenge

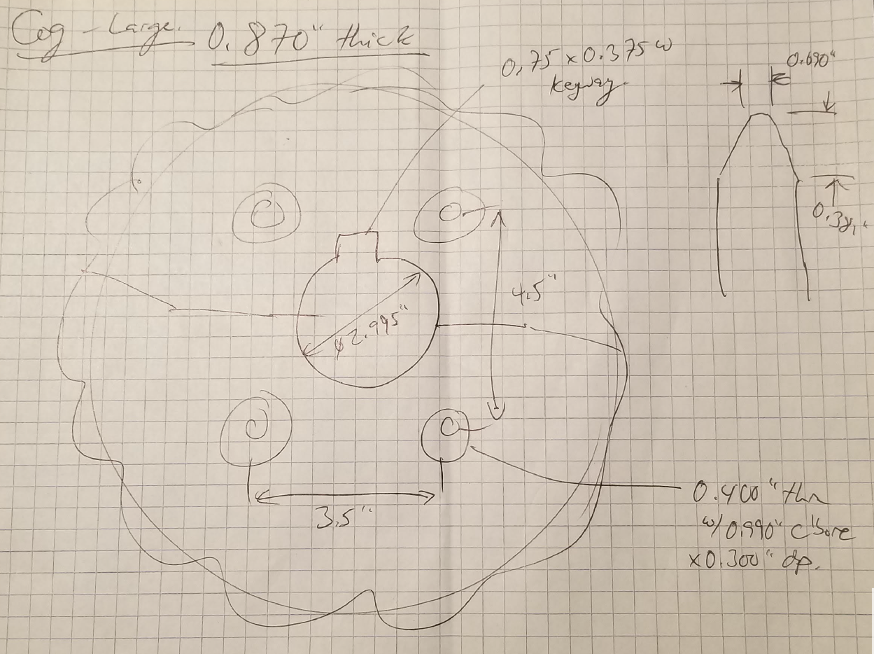

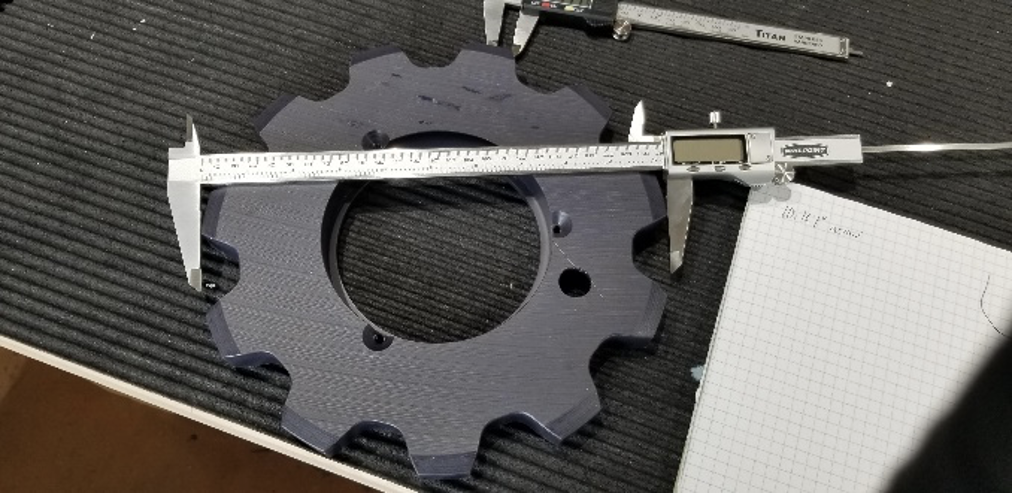

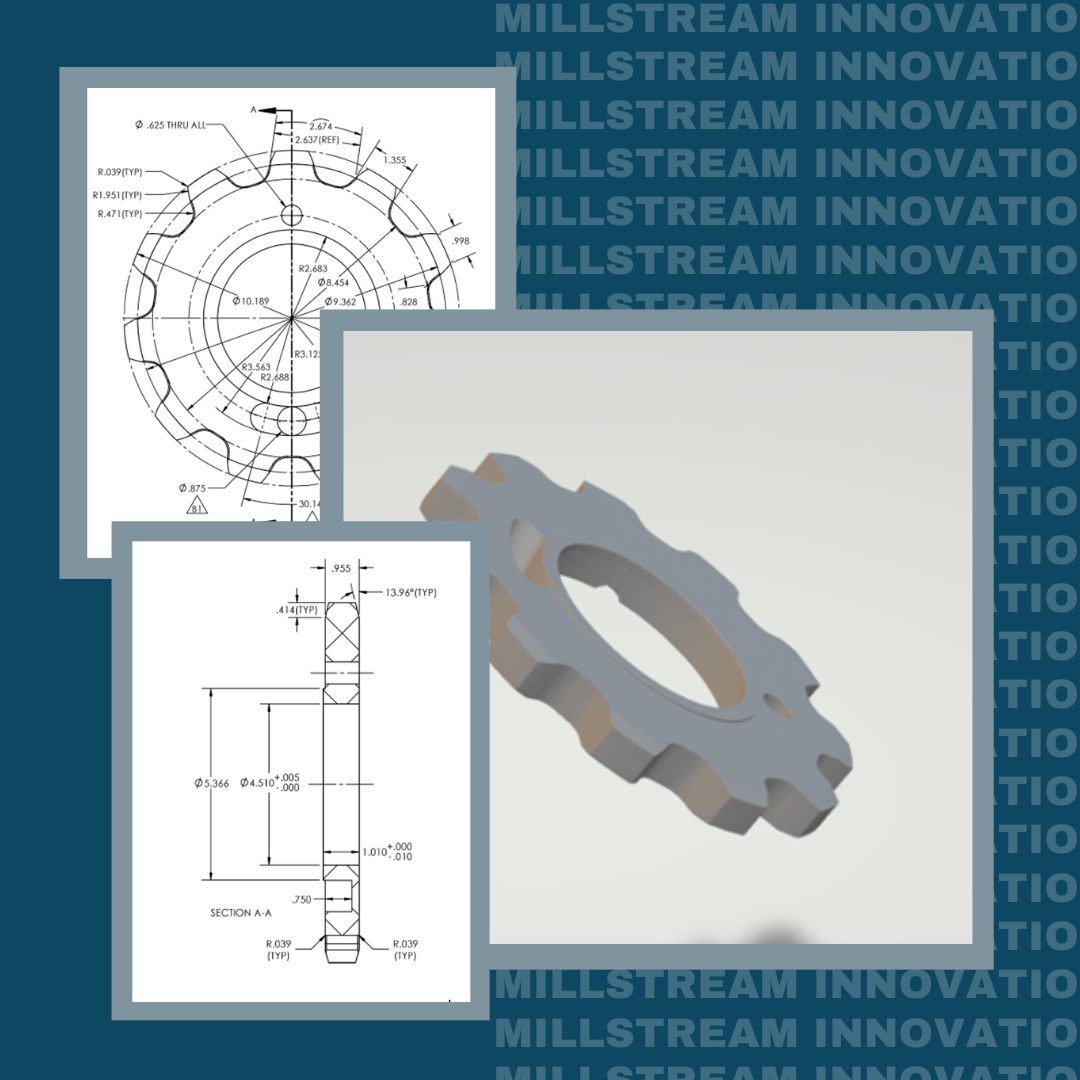

Millstream’s Approach

The Result

Minimized Downtime

The innovative approach significantly reduced retrofitting time, minimizing downtime for the wastewater treatment facility.

Enhanced Reliability

Thordon Regular material and precision engineering ensured that the new sprocket exceeded the performance of the original, contributing to enhanced system reliability.

Adaptability for Future Retrofits

The methodology developed by Millstream showcased adaptability for future retrofitting projects where original drawings might be unavailable.