Mastering The Flow: Millstream Engineering & Paravalves’ Innovative Partnership

Mastering The Flow: Millstream Engineering & Paravalves’ Innovative Partnership

In our ongoing series to spotlight the exceptional partners of Millstream Engineering, we recently introduced Paravalves in our “Partner Profile.” As a frontrunner in the design and manufacturing of industrial valves, Paravalves epitomizes innovation and reliability, offering tailored solutions that can also address the unique challenges faced by the hydropower sector.

Their commitment to excellence and customer-focused approach aligns perfectly with our values at Millstream Engineering, making them a vital part of our network. The collaboration between Millstream and Paravalves promises to bring forward advanced solutions, enhancing the operational efficiency and reliability of hydropower utilities and equipment OEMs alike. This partnership underscores our dedication to sourcing and integrating the very best in the industry, ensuring that our clients always have access to leading-edge technology and expertise.

Sluice Gate Applications for Hydropower

In the realm of hydropower operations and maintenance, the efficiency and reliability of water control systems are paramount. Paravalves stands out in this sector with their Frontgate FX series of sluice gates, specifically the FX3 and FX4 models, designed to meet the varied needs of hydropower utilities and equipment OEMs. These models are crafted with precision and innovative features that make them particularly advantageous for applications in water isolation and flow control.

FX3 Channel Sluice Gate – The Three-Side Sealing Solution

The FX3 model is engineered for channel applications, featuring a three-side sealing design. This model is particularly suitable for scenarios where precise flow control and isolation are required in water channels. Its construction allows for installation with wall anchors or embedded in concrete, providing flexibility depending on the specific infrastructure needs. The design adheres to AWWA standards, ensuring compatibility and reliability in a wide range of operational contexts.

FX4 Wall Mounted Sluice Gate – Four-Side Sealing for Enhanced Control

The FX4 penstock, on the other hand, offers a four-side sealing capability, making it ideal for more demanding applications where a higher degree of isolation is necessary. This model’s design supports bi-directional sealing, offering robust performance in both isolation and flow control. Like the FX3, it can be installed with wall anchors or embedded in concrete, and is designed according to AWWA standards, ensuring a high level of operational reliability.

Unique Features and Customization

Both models come in sizes up to 3000x3000mm and can handle pressures up to 10mwc. They can be fabricated from a range of materials, including carbon steel, stainless steel, and even more specialized options like DUPLEX or SUPERDUPLEX for seawater applications. One of the standout features of the FX series is their customization capability. Paravalves offers the flexibility to tailor these sluice gates to specific project requirements, including the choice between round or rectangular passages, various types of spindles and actuators, and a wide range of accessories.

The operation of these sluice gates can be manual, pneumatic, hydraulic, or electric, with interchangeable actuators even without dismounting from the pipeline. This flexibility ensures that the sluice gate can be easily integrated into existing systems or adapted for future upgrades. Their design also includes an epoxy coating for carbon steel components, enhancing durability and lifespan.

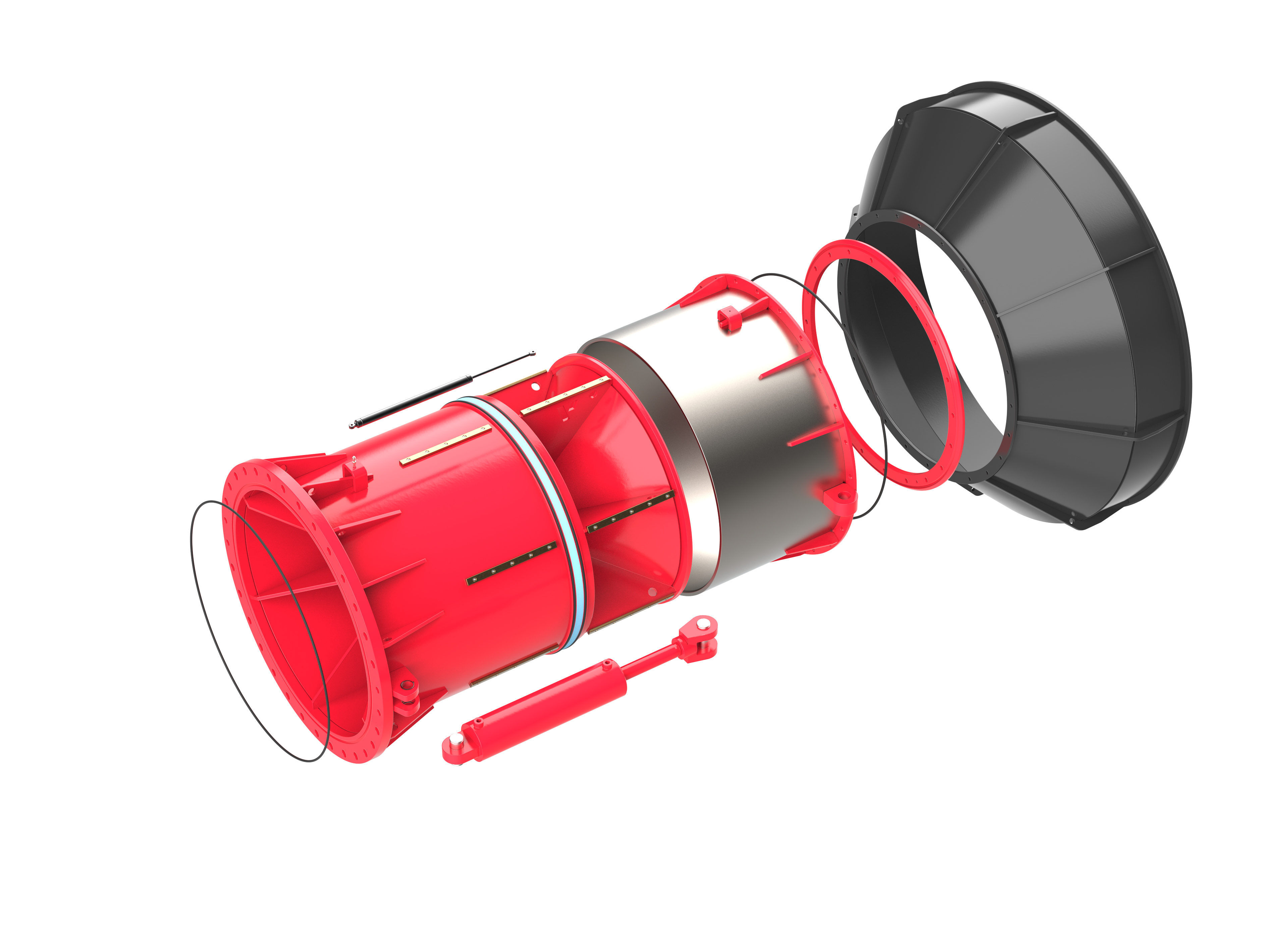

Fixed Cone Valve Applications for Hydropower

The URA series by Paravalves, including Howell-Bunger Fixed Cone Valves, is engineered for hydroelectric stations, offering precision in water level control and turbine bypass applications. With features like a high discharge coefficient, customizable up to DN2000, pressures up to 25bar, and a variety of materials, these valves ensure efficient water flow discharge and environmental protection. Options include moving or embedded hoods, soft or metal seats, and bronze guides for smooth operation, alongside tailor-made solutions like flow regulation, diverse end connections, and international standard flange drillings, all with protective epoxy coatings.

Application and Industry Fit

The FX series sluice gates and URA fixed-cone valves are not just about technical specifications; they are about providing solutions that fit the operational needs and challenges of the hydropower market.

Paravalves‘ commitment to innovation and customer-specific solutions makes these innovative sluice gates and valves particularly appealing for hydropower applications. Their approach to design and manufacturing ensures that each sluice gate and valve assembly is crafted to meet the exact needs of our customers.

Millstream Engineering stands at the forefront of bringing these innovative FX Series Sluice Gates and URA fixed-cone valves to the Canadian market. Our partnership with Paravalves not only ensures access to these exceptional valve solutions but also guarantees a level of expertise and support unmatched in the industry.

We invite you to leverage this opportunity to enhance your operational efficiency, reduce maintenance costs, and ensure reliability in your processes. Contact Millstream Engineering today for a no-cost application review. Our team is dedicated to understanding your unique challenges and recommending valve solutions that are tailored to your specific needs.

Search

Recent Posts

- Thordon Bearings in Large Valves

- Introduction to Slurry Valves: All about them, and why Dmmond valves are good

- Intro to Paravalves – Applications for Industrial

- Mastering The Flow: Millstream Engineering & Paravalves’ Innovative Partnership

- Thorseals: Revolutionizing Hydraulic and Pneumatic Cylinder Maintenance