Thorseals: Revolutionizing Hydraulic and Pneumatic Cylinder Maintenance

Thorseals: Revolutionizing Hydraulic and Pneumatic Cylinder Maintenance

The Age-Old Problem of Cylinder Sealing

Leakages can create hazardous conditions, necessitating the continual replenishment of expensive fluids or the generation of additional compressed air. Moreover, the disposal of hydraulic fluids now carries significant environmental implications. Internal leaks degrade equipment performance, causing cylinder drift and overheating, which in turn necessitates frequent adjustments and ultimately, shutdowns for repairs.

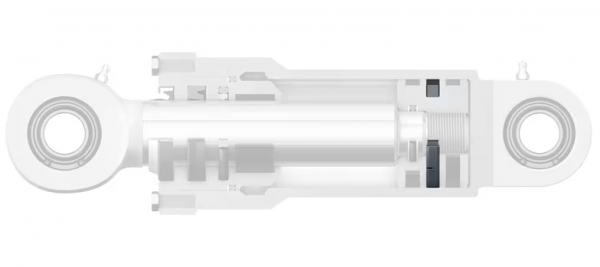

Enter Thorseals: The Modern Solution

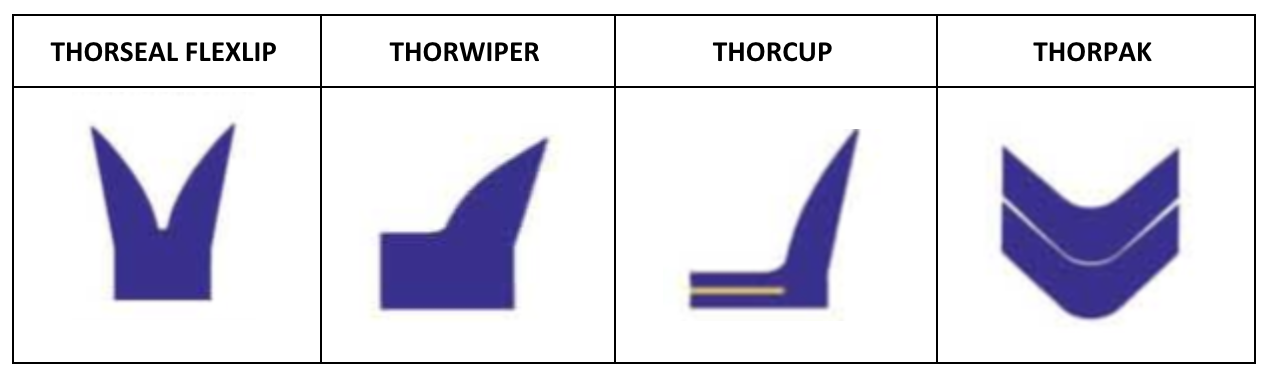

Key Features of Thorseals

- Stability in Hydraulic Fluids: The non-absorbent, oil-resistant nature of the Thorseal polymer ensures that seals maintain their integrity without swelling, softening, or extruding due to fluid absorption.

- Lifetime Self-Lubrication: By incorporating self-lubricating particles throughout the polymer, Thorseals minimize friction, heat, and wear on both the seal and cylinder, extending the service life of the machinery.

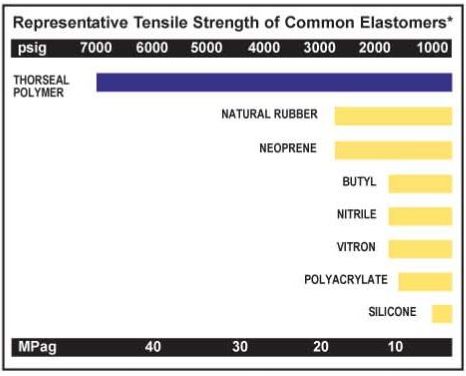

- High Strength and Toughness: Designed to withstand shock loads and high pressures, Thorseals resist extrusion and damage to their tapered lips, avoiding the common pitfalls of fabric-reinforced seals that can contaminate hydraulic systems.

- Indefinite Shelf Life: Unlike rubber seals, which can degrade over time, Thorseals retain their performance characteristics indefinitely, ensuring they are as effective years from storage as on the day they were made.

- Ease of Installation: The robustness of the Thorseal polymer simplifies installation processes, reducing the risk of damage during fitting and further lowering maintenance times and costs.