From Problems to Solutions: Optimizing Water Filtration in Hydroelectric Plants

From Problems to Solutions: Optimizing Water Filtration in Hydroelectric Plants

Deciding on a Solution

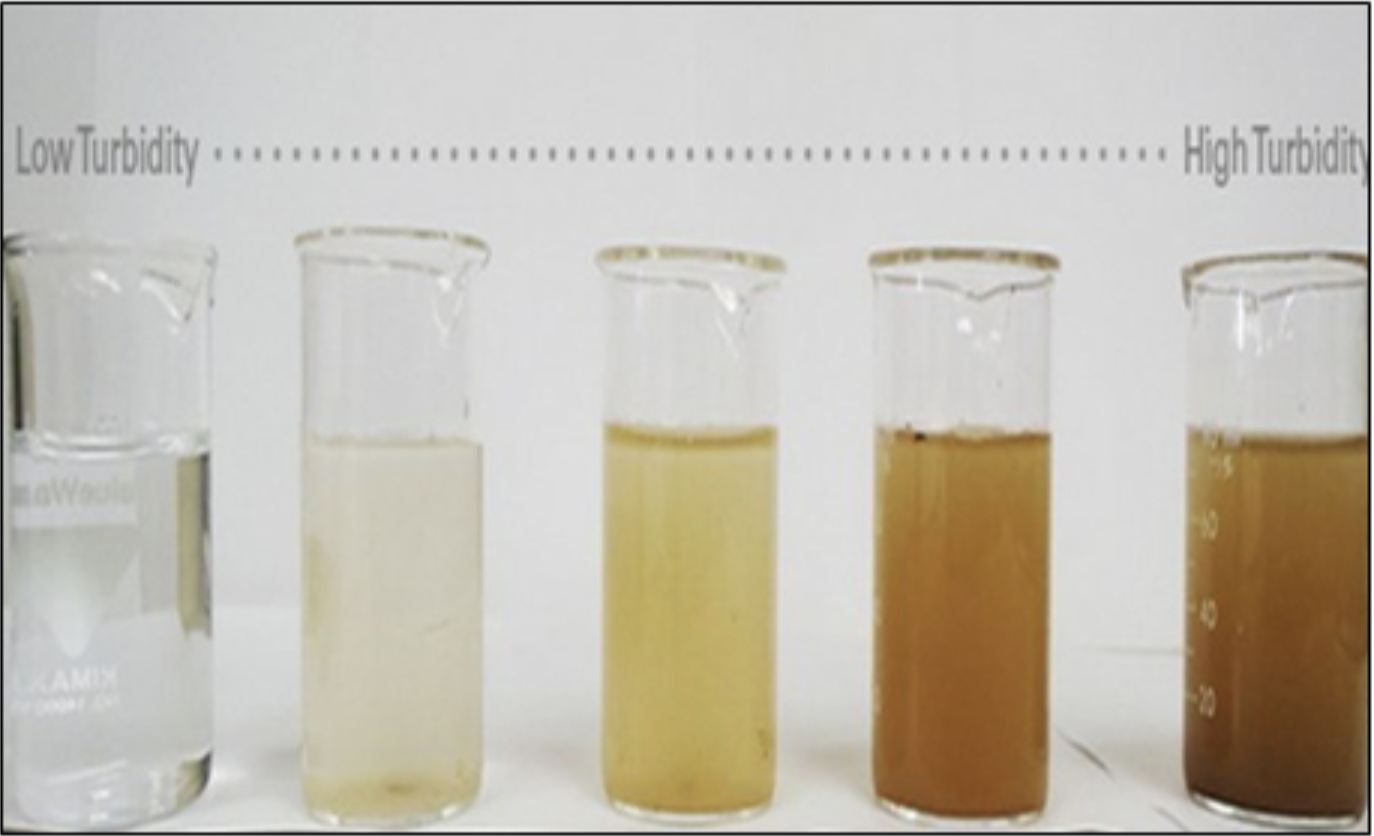

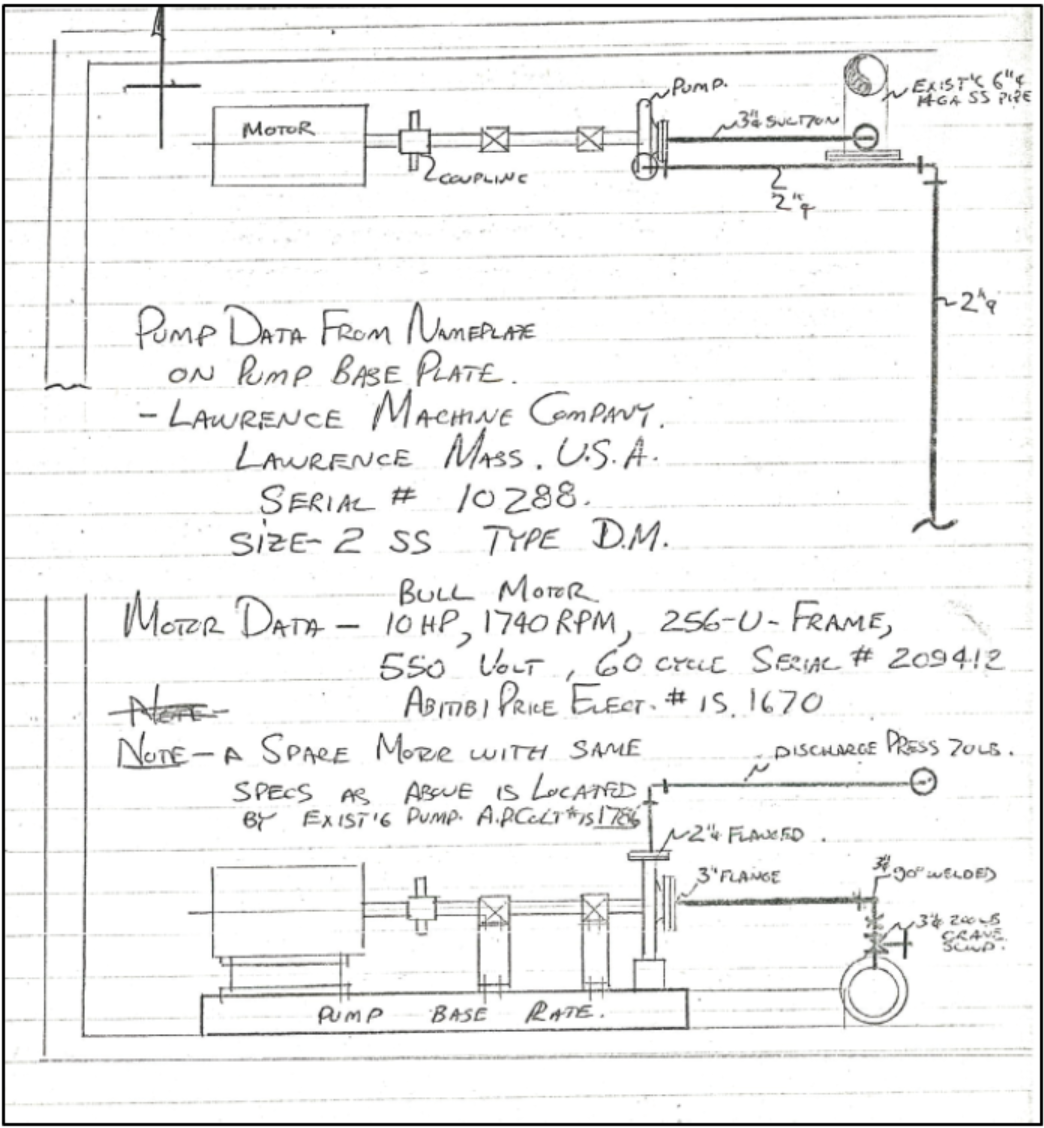

Remember, a good solution is unique to every plant, turbine, and situation. The best solutions generally involve well-arranged equipment, neat and tidy piping runs, and provide flexibility to accommodate changing site conditions. Easy access for service and maintenance, integrated monitoring, and alarms interconnected with the customer SCADA system are also crucial.

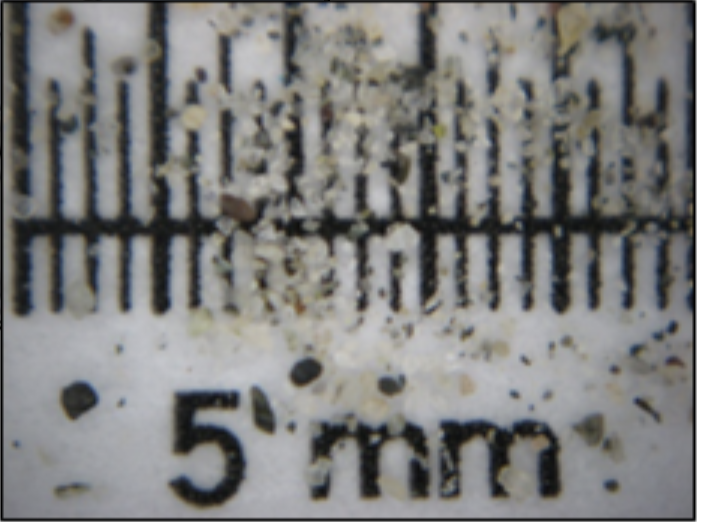

One such solution is using a centrifugal separator, which is known for its continuous operation, controlled flow, and robust design. It’s low maintenance, simple to operate, and has no internal moving parts that could fail, making a complete loss of flow to bearing and seal almost impossible. Thordon’s design removes particles of 1.2 specific gravity or higher and greater than 100 microns in size with 95 – 98 % efficiency, depending on flow rates. Higher flow rates translate into higher filtration efficiency.

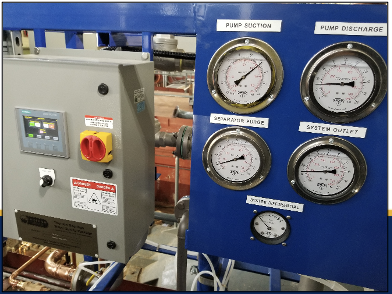

Thordon’s Hydro-Specific Water Quality Packages (WQP)

Thordon offers Hydro Specific Water Quality Packages (WQP) that come in double and single configurations for redundancy. Their modular design allows for easier customization, and additional instrumentation provides more control and feedback to interface with turbine control systems. It also has the capability to regulate both flow rates and pressure, making it suitable for shaft seal and/or bearing supply applications.