Short outages, long product lead times?

Short outages, long product lead times?

Identify the Need

Uh oh, we have bushings that are more worn out than we thought. We need replacements quickly!

Sourcing & Ordering

Where can we get replacement parts from? The original drawing calls out some unknown material, and we have no idea who can supply it!

Shipping & Delivery

Ok - we found a supplier, but they need 8 weeks to finish machine the new bushings, and we only have 2 weeks left in our planned outage...

Installation & Testing

Even if the supplier can rush ship them, we still need time to get them installed. We need more time!

Each step adds to the downtime, and with the added unpredictability of shipping and potential manufacturing delays, the scheduled outage can extend way beyond the planned duration.

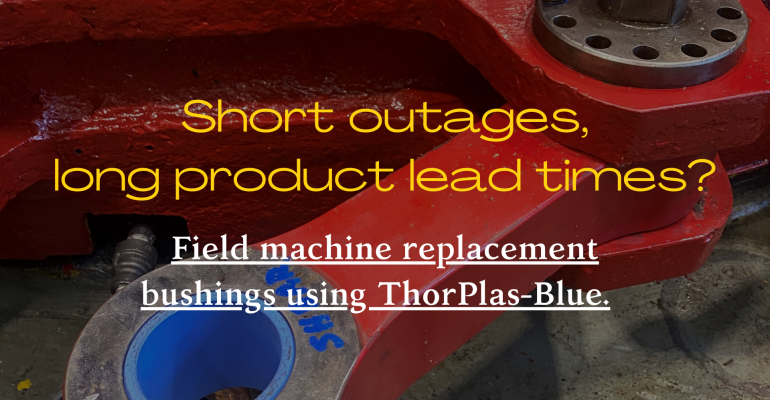

The Solution: ThorPlas-Blue Rough Tube Stock