Waterjet Cutting: A Versatile Approach for Cutting Flexible Elastomer Components

Waterjet Cutting: A Versatile Approach for Cutting Flexible Elastomer Components

When faced with complex part geometry, or the need to get the best possible material utilization, waterjet cutting can be a great solution to get rough shapes ready for final machining from block or sheet stock material, or in some cases even producing the fully finished parts.

The use of an extremely high-pressure and very thin jet of water to cut through material quickly and precisely is a fascinating technology that offers some unique advantages for cutting flexible materials. Especially when working with the Thordon elastomer materials for bearings & wear pads, it can be a great time and cost savings approach to manufacturing. A few of the benefits include:

Versatility with Different Materials

Eliminate Heat-Affected Zones

Traditional machining can generate heat, which may cause melting or deformation in flexible materials. Waterjet cutting doesn’t produce a heat-affected zone, making it well-suited for plastics and other heat-sensitive materials.

Minimize Material Waste

Parts can be nested very tightly together from a single sheet, allowing for minimal material loss.

CAD/CAM Integration

For simple 2D shapes a basic CAD drawing can be used to directly generate the cutting path, and with more advanced 5-axis waterjet systems, a 3D CAD model can be used to develop the toolpath required to cut more complex shapes and angles.

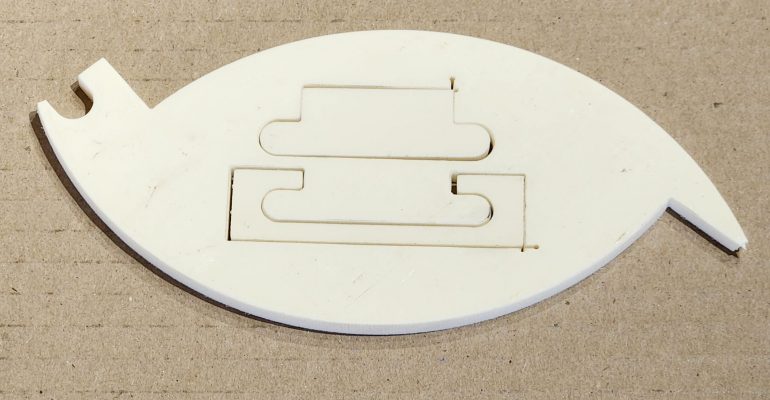

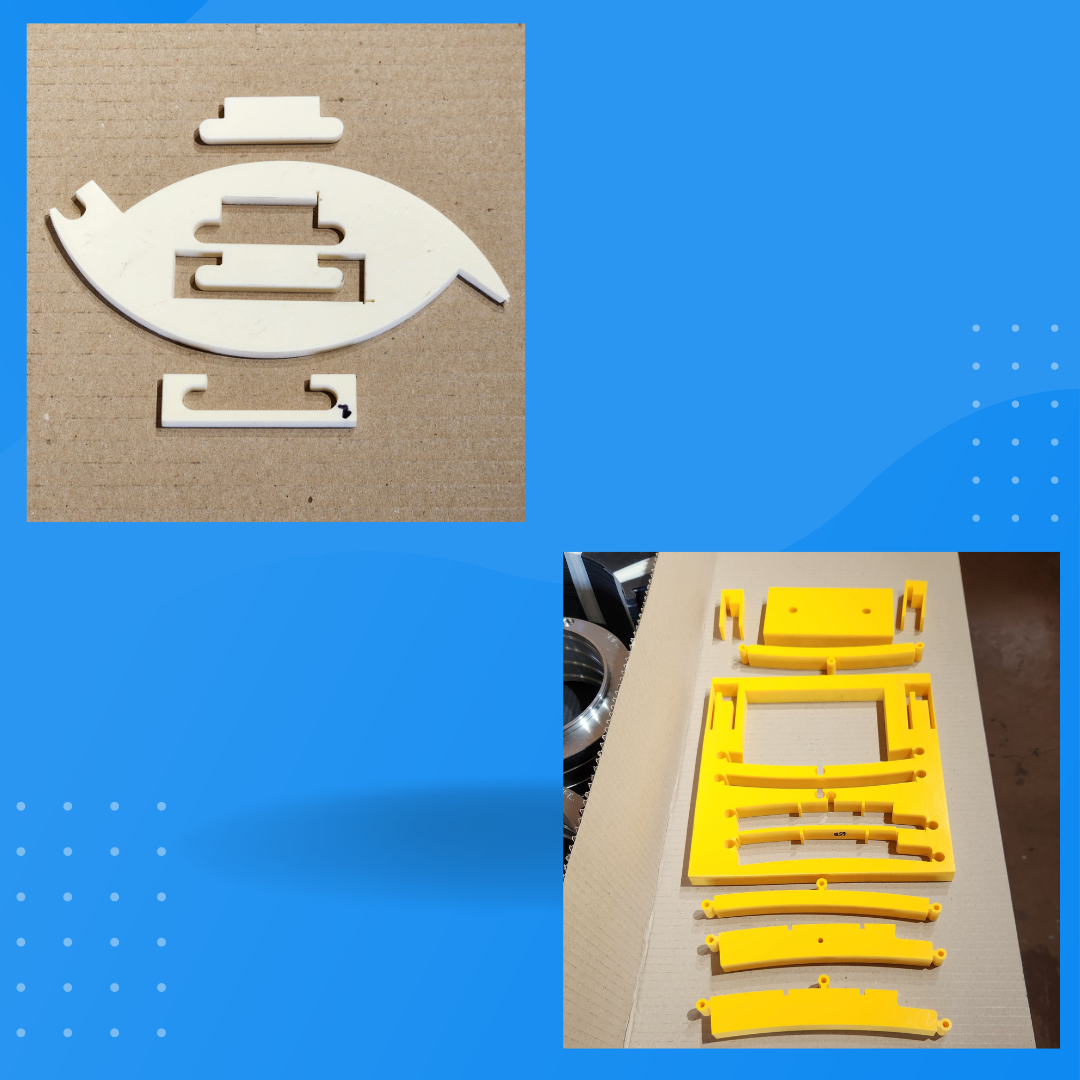

Check out some of the shapes we have produced from Thordon elastomers using water jet cutting. In some of the components, you can see that small circular clamping tabs have been left on the parts to help with work holding for further machining operations to be done on a conventional CNC mill. These tabs can be easily cut-off later by hand once the parts are fully machined.

Waterjet cutting has revolutionized the manufacturing of elastomer applications, enabling precision, versatility, and cost-efficiency. When combined with conventional machining, it unlocks the potential for streamlined production processes and significant cost savings. Millstream Engineering offers the expertise and cutting-edge technology to deliver precisely crafted components from Thordon elastomer materials. Whether it’s wear pads, fixturing components, bearings, bushings, or impact-absorbing bumper pads, Millstream Engineering is here to solve your equipment reliability challenges.

Get in touch today and your machinery will thank you!